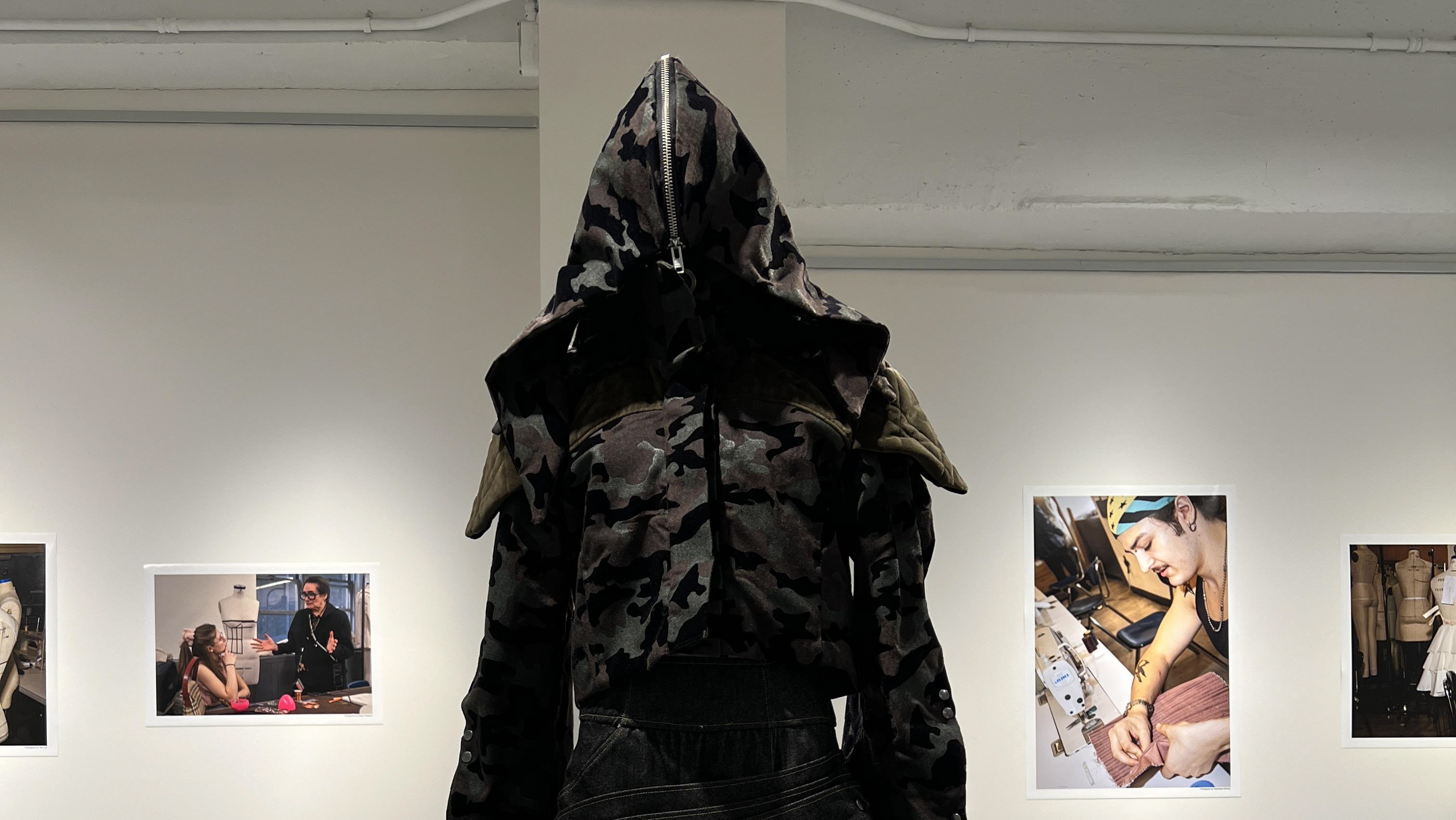

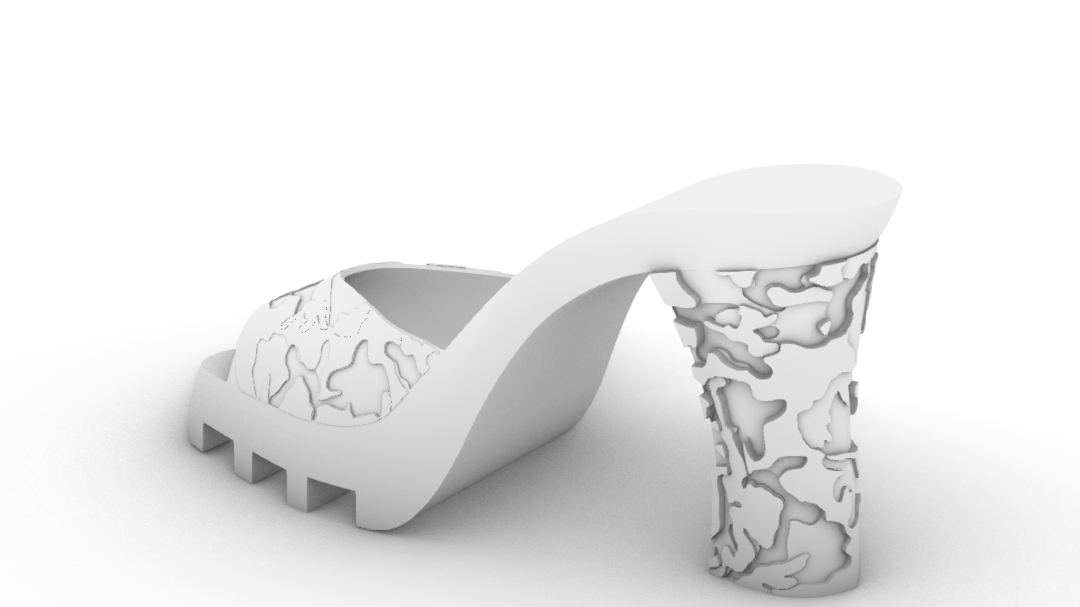

In sustainable design, the ideal product has a net-positive impact on the environment. Net positive buildings, which generate more energy than they use, provide physical examples of sustainable innovation. I sought to avoid the creation of any new waste; developing a business model which finds new use cases for existing material. Whether reconstructing fabric into a zero-waste garment or funding it’s transformation into shoddy material, the Re-Style model actively reduces the amount of textiles in recycling limbo.

Efficient manufacturing is sustainable manufacturing, with modern technologies providing efficiency by reducing materials, labor, space and energy consumption. In discussion with the Brooklyn-based recycling company FabScrap, I learned how reliant their business model is on volunteer textile sorters. Through volunteering as a textile sorter, I realized how common the recycling-inhibiting materials such as plastic, metal and elastic appear in textile waste, and how critical textile sorting is to recycling.

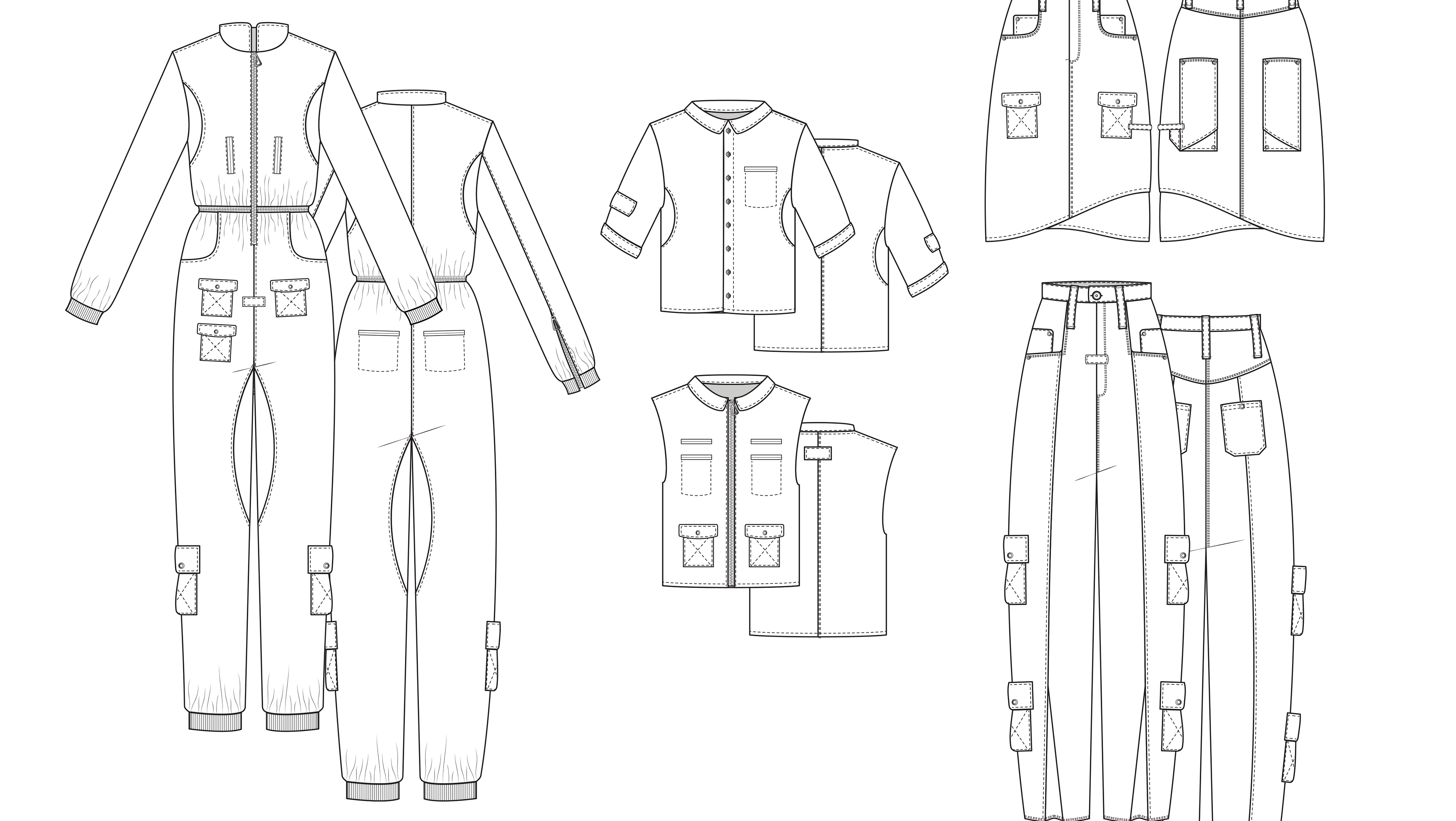

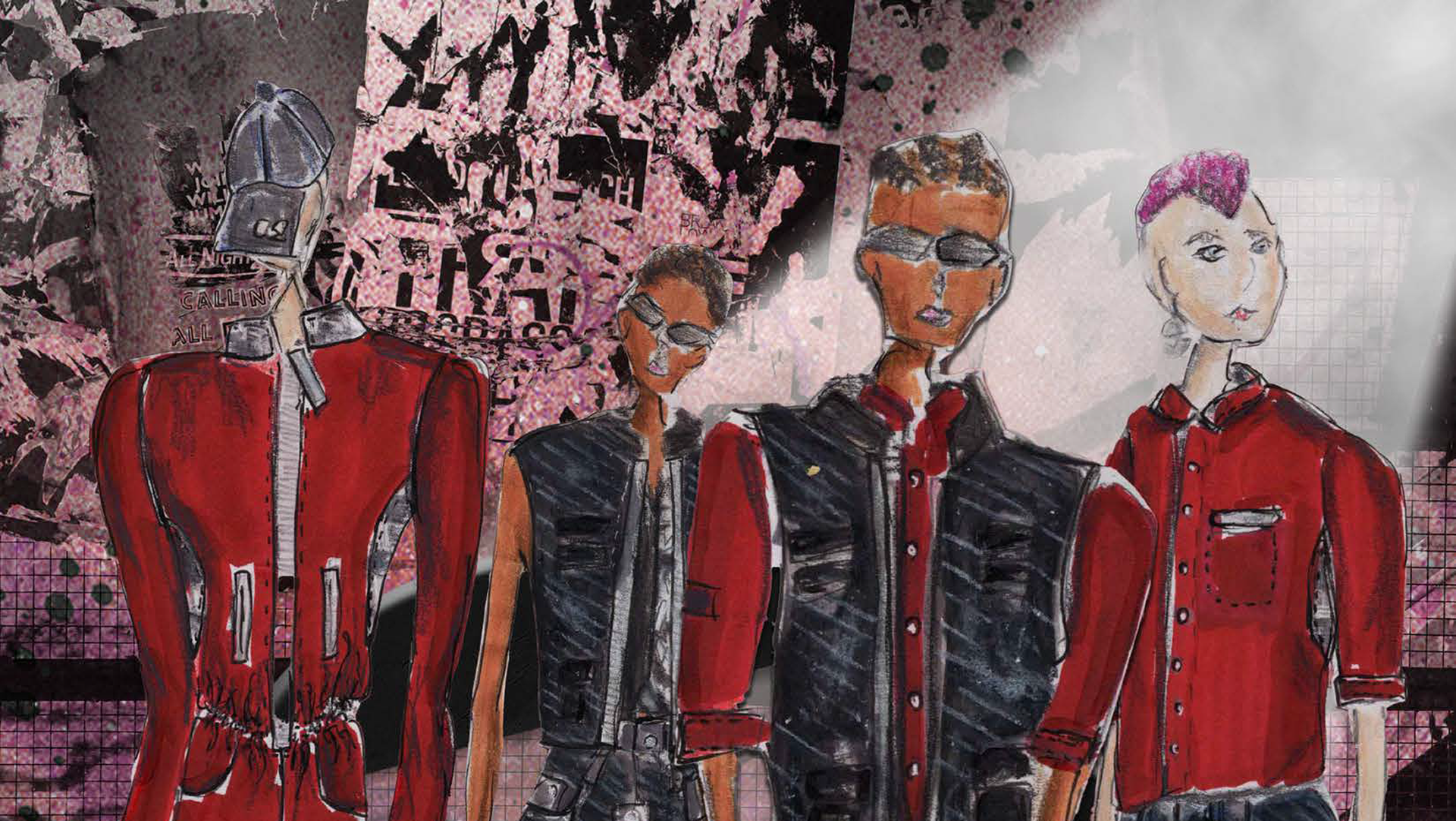

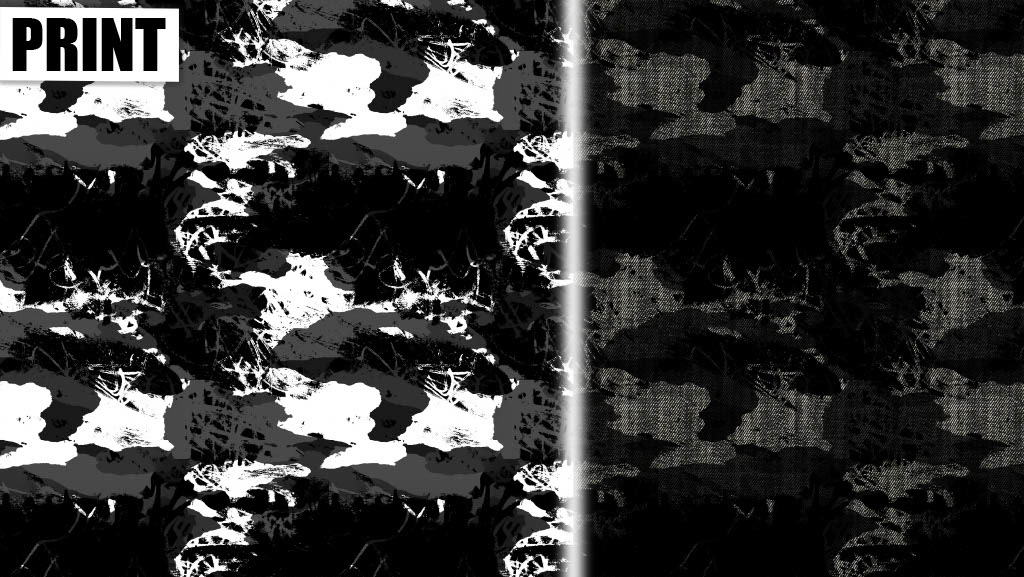

Re-Style seeks to support inefficient recycling process such as fabric sorting through the marketing and sale of re-imagined garments. Only a photographed swatch and digital pattern are needed to create realistic approximations of what donated fabric could be constructed into. Automating the product visualization, marketing, and pattern-layout process, we minimize the labor needed to realize the potential value of unused textiles, only manufacturing when a customer selects an available fabric and style. Our marketplace of Re-Styled garments creates new value from fabric waste, subsidizing essential recycling tasks.